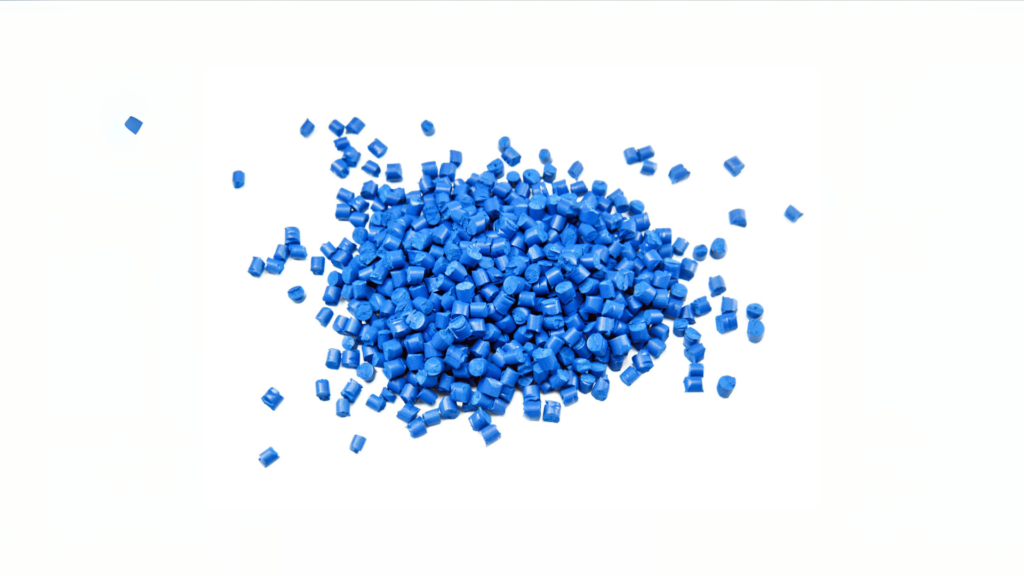

Acrylonitrile Butadiene Styrene (ABS) plastic granules are increasingly in demand for modern manufacturing. Virgin and recycled ABS plastic granules mostly get involved in sustainable production. Understanding the characteristics and applications of these materials is important. Industries worldwide also have shifted toward more environmentally conscious practices.

Virgin ABS granules come directly from petroleum-based raw materials. They offer superior mechanical properties and consistency in manufacturing processes. These pristine pellets provide excellent impact resistance, structural stability, and aesthetic appeal. These characteristics make them ideal for applications requiring a high-quality finish. The controlled manufacturing environment ensures consistent colour, density and mechanical properties. Those are important for industries: automotive parts manufacturing, consumer electronics and medical device production.

Yet the growing sustainability leads to increased adoption of recycled ABS granules. These materials occur from post-industrial or post-consumer waste. Then, they undergo careful processing to maintain quality while reducing environmental impact. Modern recycling technologies significantly improve the quality of recycled ABS. They narrow the performance gap with virgin materials. Advanced sorting, cleaning, and reprocessing techniques ensure that recycled granules meet stringent industry standards.

The market has witnessed a notable shift in perception regarding recycled ABS granules. The granules are traditionally viewed as inferior alternatives. Yet technological advancements in recycling processes have enhanced their reliability and application scope. Many manufacturers now blend virgin and recycled ABS. Their goal is to optimise cost efficiency while maintaining product quality. This hybrid approach makes companies reduce their carbon footprint without compromising performance standards.

Cost considerations play a significant role in material selection. Virgin ABS typically commands premium prices due to its consistent quality and reliable performance. Recycled variants often present a more economical alternative. Yet prices can fluctuate based on availability and quality grades. The cost differential encourages manufacturers to develop innovative solutions. The expected solutions are to maximise the use of recycled content while meeting product specifications.

Environmental benefits of recycled ABS include beyond waste reduction. The production of recycled granules consumes significantly less energy compared to virgin material manufacturing. It results in lower greenhouse gas emissions. Additionally, the reduced demand for raw petroleum products helps conserve natural resources. It also minimises environmental impact.

Quality control remains paramount in both virgin and recycled ABS production. Manufacturers implement rigorous testing protocols. It is to ensure material properties meet specified requirements. The parameters are melt flow index, impact strength, and thermal stability. They undergo regular monitoring. The aim is to maintain consistency across production batches.

Looking ahead, the industry continues to invest in research and development to enhance recycling technologies and material properties. Innovations in chemical recycling and material recovery promise to further improve the quality of recycled ABS granules. Sustainability requirements become more stringent. So, the balance between virgin and recycled materials will likely shift further toward recycled content.

The choice between Virgin and recycled ABS plastic granules depends on specific application requirements, regulatory compliance needs, and sustainability goals. The integration of recycled content in manufacturing processes will continue to evolve. It hopefully drives innovation in material science and processing techniques.